Continuous improvement as a philosophy is based on the constant tendency towards the best, and continuous improvement is a twin that runs parallel to the requirements of responding to change because it is the constant in life. Therefore, improvement can be viewed as a stage with no known end for organizations seeking to compete and win the largest share of the market. However, the view of improvement varies in light of the philosophies, applications and models of management in general [i]. Accordingly, researchers have differed in their opinions about the nature of the relationship between continuous improvement and the administrative concepts associated with it. On the one hand, continuous improvement has been considered as part of quality management [ii]. A group of studies have also indicated that the application of continuous improvement often falls within the preparation for larger systems such as lean management and total quality management (TQM) [iii]. Other studies have indicated that continuous improvement involves several strategies, namely: total quality management (TQM), six sigma and lean manufacturing [iv]. Studies have also indicated the existence of many continuous improvement programs or methodologies such as: the lean concept (Lean), six sigma and lean six sigma [v] In a second study: Lean Manufacturing, Six Sigma, Lean Six Sigma and the Balanced Scorecard [vi], studies also indicated that continuous improvement appeared in different forms in many different organizations. On the one hand, continuous improvement was considered an integral part of total quality management, and on the other hand, it was considered part of the Lean Philosophy, while other researchers indicated that continuous improvement is an independent path in itself; as continuous improvement was referred to as an umbrella for a wide range of tools and practices that can be used to improve manufacturing performance. [vii]

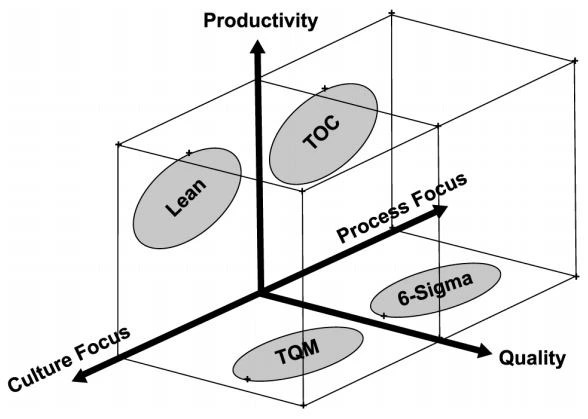

Here, one point of view indicated that continuous improvement (Kaizen)[viii] and total quality management are two independent concepts. In the literature, the topic of continuous improvement was addressed as an important element of total quality management, as Kaizen is one of the reference points within Deming’s 14 points for total quality management; Deming pointed out that constant and permanent improvement requires a type of continuous improvement methodologies such as Kaizen, and therefore Kaizen is a sub-concept of Total Quality Management [ix]. As for studies that considered continuous improvement as an “umbrella” for other concepts, there are two common paths to continuous improvement, the first is continuous productivity improvement, which includes the concepts of lean thinking and the theory of constraints, and the second path is continuous quality improvement, which includes the concepts of Total Quality Management (TQM) and Six Sigma. Flexible thinking and the theory of constraints have a primary impact on productivity and a secondary impact on quality, and conversely, the concepts of Total Quality Management and Six Sigma have a primary impact on quality and a secondary impact on productivity. It can also be said that the concepts of the theory of constraints and Six Sigma focus primarily on the process, while both the lean concept and Total Quality Management focus on culture. The following figure illustrates the above: [x]

Figure (1): The impact and focus of continuous improvement strategies

Clearly, for any organization to succeed, it must improve both quality and productivity, and therefore it must include elements of both concepts. Also, a culture-focused strategy requires greater empowerment of the organization’s leadership and the ability and willingness to distribute knowledge, and a process-focused strategy is easier to have a directive leadership style, and therefore requires communicating input into new procedures and processes.[xi]

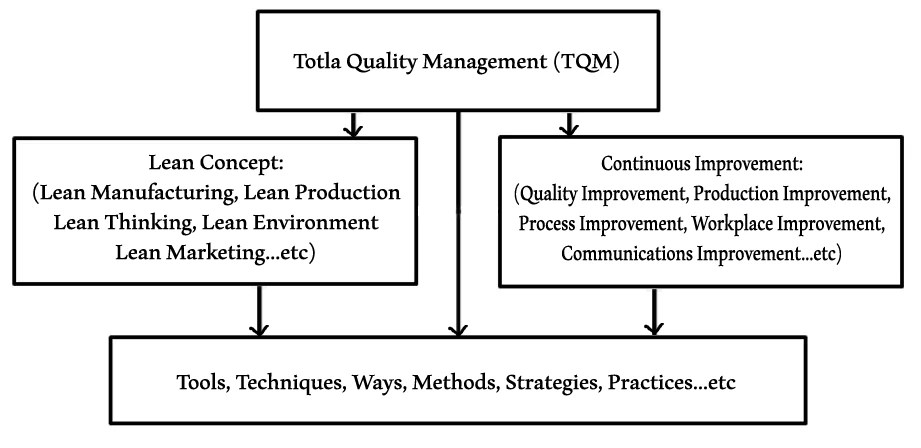

By reviewing previous studies, it becomes clear that total quality management is the umbrella that includes many concepts such as continuous improvement and its branches and the concept of (lean) and its branches. In turn, continuous improvement and the concept of (lean) include and share a large number of tools, techniques, or methods…etc., as shown in the following figure:

Figure (2): The relationship between continuous improvement and other concepts

The term “continuous improvement” originated from the Japanese term (Kaizen) developed by Masaki Imai, who is considered the godfather of continuous improvement. The word Kaizen consists of two parts: the first (Kai) means “change” and the second (Zen) means “for the better”[xii]. It is not a new concept; the roots of the concept go back to the 1980s when Masaki Imai defined it as: gradual improvement that includes everyone[xiii]. Studies have indicated that continuous improvement can be evolutionary or revolutionary; the evolutionary concept indicates that improvements occur as a result of continuous gradual changes, while the second (revolutionary) concept indicates that major improvements occur as a result of an innovative idea or technology, or simply as a result of gradual, cumulative improvements[xiv]. Continuous improvement practices are divided into four structures (top management, culture, strategy, people); Continuous improvement requires support from senior management by providing the necessary resources such as financial resources, workspaces, etc., which allows for effective cooperation between employees. One of the characteristics of a successful continuous improvement program is the existence of a culture of improvement and effective participation, where all employees are encouraged to contribute to improving processes. Continuous improvement activities must also be linked to the organization’s strategic goals. Continuous improvement includes the use of cross-functional work teams or temporary working groups to solve problems. [xv]

After reviewing the literature review studies, we noticed that there are a large number of definitions that have been used to indicate continuous improvement. For example, previous studies indicated that continuous improvement is a process of continuous and purposeful gradual innovation that spreads throughout the organization. Continuous improvement also refers to the systematic pursuit of finding and using methods that help achieve continuous process improvement. As it constitutes the backbone of quality management and innovative practices, continuous improvement is the ongoing effort that allows industrial companies to focus on building a bright future by improving processes, products and/or services through incremental or radical improvements[xvi]. Continuous improvement is also a structured process – based on the equipment – that seeks to improve production efficiency by identifying and eliminating waste and losses throughout the life cycle of the production system using employee participation – based on teams – across all levels of the organizational structure[xvii]. The culture of continuous improvement involves sustainable improvements that aim to eliminate waste in all organizational systems and processes, and includes all members of the organization working together to achieve improvements while avoiding the use of large investments as much as possible.[xviii]

The study of Sanchez and Blanco (2014) mentioned the most important previous definitions that appeared in the stage of developing the concept of continuous improvement:

Table (1): The most important definitions of continuous improvement

| Author | Definition |

| (Deming, 1982) | Continuously and permanently improve the production and service system (the fifth principle of transformation) |

| (Imai, 1989) | Continuous improvement that involves everyone in the company (including employees and managers) |

| (Bessant et al, 1994) | A process of continuous, focused, incremental innovation at the company level |

| (Juergesen, 2000) | Improvement contributions that increase success and reduce errors |

| (Bessant et al, 2001) | A specific set of actions that can help an organization improve what it is currently doing |

| (Dahlgaard et al, 2002) (Brunet and New, 2003) | Small, ongoing changes to better-defined and sustained activities, outside the explicit contractual roles of the contributor, to identify and achieve outcomes that are believed to contribute to the achievement of organizational goals |

| (Boer and Gertsen, 2003) | The planned, organized, and systematic process of continuous, gradual, company-wide change of existing practices aimed at improving company performance |

| (Chang, 2005) | A cycle consisting of: establishing customer requirements, meeting requirements, measuring successes, and continuing to verify customer requirements to find areas for improvement |

| (Bhuiyan et al, 2006) | A culture of sustainable improvement aims to eliminate waste in all organizational systems and processes, and includes all participants in the organization |

| (Manos, 2007) | Subtle, incremental improvements made over time |

Studies have indicated that although there is a difference in the definitions of continuous improvement programs, the ultimate goal and purpose are the same [xix]. Regardless of the researchers’ viewpoints on defining continuous improvement, it can be noted that continuous improvement is a cycle and not just an action, i.e. it is an ongoing activity that must be carried out over time. It should not be an independent activity, and here all people in the organization must participate in the continuous improvement cycle. The organization must also focus on eliminating losses and identifying new areas for improvement within the framework of continuous improvement. Accordingly, it can be said that continuous improvement is an ongoing process of improvement in the company that is carried out in partnership with all employees [xx]. In this series of articles, we have relied on the comprehensive definition of continuous improvement, which is considered any approach or program that continuously seeks to improve all operations by improving the level of quality, delivery, productivity, customer satisfaction, or reducing lead times, costs, and defects [xxi]. The improvement process is not a random process; rather, it is a process that has several requirements and faces several obstacles, and its implementation results in many benefits [xxii].

References

The primary source of the article is: Al-Farhan, Mohannad. (2022). The role of continuous improvement technique on organizational learning process: An applied study on the electrical appliances manufacturing sector. Master’s thesis, Faculty of Commerce – Menoufia University. / The thesis can be obtained by clicking here.

[i] بكر، نادية عبد الخالق. (2016). مدخل التحسين المستمر (Kaizen) وأثره على أداء المنظمات (بالتطبيق على الشركة القابضة لكهرباء مصر). المجلة العربية للإدارة، 36 (1)، ص244.

[ii] Tavana, M. et al. (2021). An integrated fuzzy framework for analyzing barriers to the implementation of continuous improvement in manufacturing. International Journal of Quality & Reliability Management, 38(1), p18.

[iii] Sanchez, L. and. Blanco, B. (2014). OPCIT, p995.

[iv] Brown, A. et al. (2008). OPCIT, p542.

[v] Lizarelli, F. et al. (2019). Relationship between continuous improvement and innovation performance: an empirical study in Brazilian manufacturing companies. Total quality management and business excellence, p1.

[vi] Bhuiyan, N. and. Baghel, A. (2005). An overview of continuous improvement: from the past to the present. Management Decision, 43(5), p762.

[vii] Nordin, E. and. Dervisevic, S. (2015). OPCIT, p10.

[viii] Kaizen is a Japanese word made up of two parts, (Kai) meaning improvement or change, and (Zen) meaning for the better.

[ix] Singh, J. and. Singh, H. (2013). OPCIT, p83-84.

[x] Brown, A. et al. (2008). OPCIT, p543-548.

[xi] Brown, A. et al. (2008). Ibid, p549.

[xii] Sanchez, L. and. Blanco, B. (2014). OPCIT, p987.

[xiii] Sanchez, L. et al. (2019). Barriers to effectively implementing continuous improvement in Spanish firms. Total Quality Management & Business Excellence, p1.

[xiv] Bhuiyan, N. and. Baghel, A. (2005). OPCIT, p761.

[xv] Lizarelli, F. et al. (2019). OPCIT, p4-5.

[xvi] Tavana, M. et al. (2021). OPCIT, p118-137.

[xvii] Singh, J. and. Singh, H. (2013). OPCIT, p78.

[xviii] Bhuiyan, N. and. Baghel, A. (2005). OPCIT, p761.

[xix] Lizarelli, F. et al. (2019). OPCIT, p3.

[xx] Sanchez, L. and. Blanco, B. (2014). OPCIT, p987-988.

[xxi] Nazaruk, M. (2011). OPCIT, P 211.

[xxii] محمد، حسين علي. (2021). التحسين المستمر وعلاقته بالتميز في أداء العاملين (دراسة ميدانية). المجلة العلمية للدراسات التجارية والبيئية، جامعة قناة السويس، 12 (1)، ص523.

Subscribe to get the latest blogs

*-please check the spam folder if you didn’t receive the email

Read the full series of Continuous Improvement:

1-Continuous Improvement: Introduction.

2-Continuous Improvement Concept. (This Article)

3-Determinants of Continuous Improvement.

4-The Benefits of Continuous Improvement.

5-Continuous Improvement Tools & Techniques.